Login / Register

Sanha NiroSan Press Fit Female Threaded Tee 90

Useful Information

Sanha NiroSan Stainless Steel Press Fit Installation Guide

What is a Press Fit Female Threaded Tee used for?

The Sanha NiroSan Press Fit Female Threaded Tee is a versatile fitting designed to create a branch line from a main press-fit pipeline while providing a female threaded outlet for additional connection to threaded components. This tee is ideal for integrating gauges, sensors, or other threaded devices into the press-fit piping system, offering a streamlined and efficient method to expand or modify the system.

Key Features

- Material Quality: Made from high-grade 1.4404 stainless steel for moulded parts and 1.4408 for threaded parts, ensuring superior corrosion resistance compared to conventional materials.

- Durability: Features a long service life, supported by an EPDM sealing ring known for its robustness and reliability.

- Certifications: WRAS-tested and certified, ensuring compliance with rigorous health and safety standards.

- Temperature and Pressure Ratings: Capable of handling a broad range of operating temperatures (-30 °C to +120 °C) and pressures, varying according to size (up to 40 bar for smaller diameters).

- Broad Application Spectrum: Suitable for a multitude of systems, from potable water to technical gases and cooling systems, reflecting its versatility in different industrial and commercial settings.

- Certifications: WRAS-certified, ensuring it meets the standards required for safe use in potable water systems.

Specifications

- Product Codes: 69130G151215, 69130G221222, 69130G223422, 69130G281228, 69130G283428, 69130G351235, 69130G421242, 69130G541254

- Available Sizes: 15mm x 1/2", 22mm x 1/2", 22mm x 3/4", 28mm x 1/2", 28mm x 3/4", 35mm x 1/2", 42mm x 1/2", 54mm x 1/2"

- Pressing Profile: SA, M and V Profile

- Materials: 1.4404 (AISI 316L) stainless steel

- Sealing Ring: EPDM

- Operating Conditions: Varies with diameter - up to 40 bar for ≤22 mm, 25 bar for 28–35 mm, and 16 bar for 42–168.3 mm.

- Temperature Range: -30 °C to +120 °C

- Range: NiroSan Series 9000

- Approvals: BSI / Kitemark & WRAS

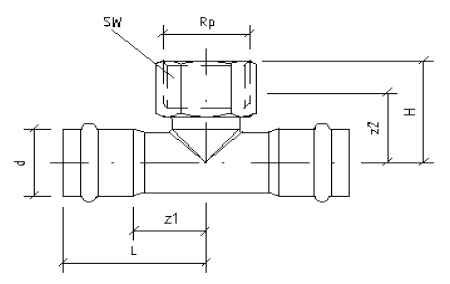

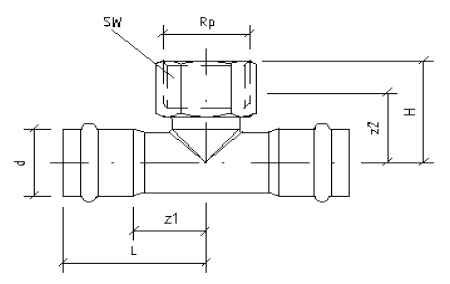

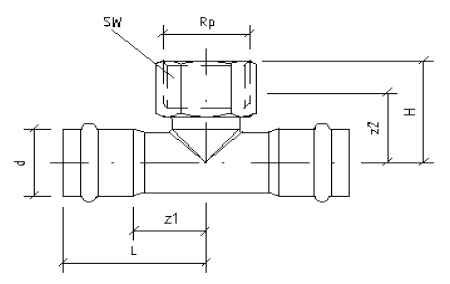

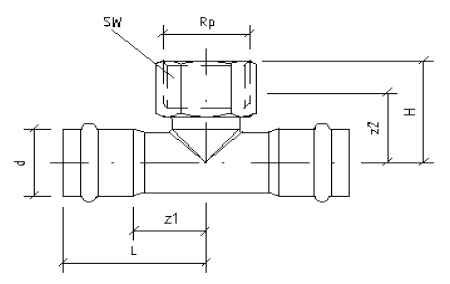

| Product Code | Sanha Code | d (mm) | Rp (inch) | H (mm) | L (mm) | SW (mm) | z1 (mm) | z2 (mm) | ||||

| 382352 | 69130G151215 | 15 | 1/2 | 36 | 47 | 24 | 22 | 23 | ||||

| 382353 | 69130G221222 | 22 | 1/2 | 41 | 54 | 24 | 26 | 28 | ||||

| 382354 | 69130G223422 | 22 | 3/4 | 41 | 54 | 32 | 26 | 26 | ||||

| 382355 | 69130G281228 | 28 | 1/2 | 44 | 60 | 24 | 31 | 31 | ||||

| 382356 | 69130G283428 | 28 | 3/4 | 44 | 60 | 32 | 31 | 29 | ||||

| 382357 | 69130G351235 | 35 | 1/2 | 47 | 65 | 24 | 35 | 34 | ||||

| 382359 | 69130G421242 | 42 | 1/2 | 50 | 77 | 24 | 39 | 37 | ||||

| 382360 | 69130G541254 | 54 | 1/2 | 56 | 89 | 24 | 45 | 43 | ||||

Installation Instructions

- Preparation: Use a roller pipe cutter or a fine-toothed saw ensuring no tarnish. Avoid high cutting speeds to prevent stainless steel sensitisation.

- Deburring: Thoroughly deburr the tube end inside and out, removing all residues.

- Insertion Depth: Mark the insertion depth on the tube or fitting, ensuring accurate installation.

- Sealing Ring Inspection: Ensure the sealing ring is correctly positioned and free from damage.

- Connection: Insert the pipe end into the fitting until it reaches the depth mark, ensuring a secure and proper fit.

For detailed installation instructions, including pressing jaw selection and pressing process, refer to the SANHA installation guide below.

Downloads