- Home

- John Guest

- John Guest Air Ring Main

John Guest Air Ring Main

The John Guest Ring Main System represents a pinnacle of innovation in compressed air distribution and pneumatic solutions. Specially designed for a diverse range of industrial, commercial, and workshop environments, this system offers unparalleled efficiency and reliability.

Key Features and Benefits

- Rapid Installation: Featuring the iconic John Guest push-fit technology, this system dramatically reduces installation time, allowing for a quick, hassle-free setup.

- Versatile Applications: Ideal for compressed air, vacuum, and inert gases, the Ring Main System caters to a variety of needs in different settings.

- Durable Materials: Constructed with high-quality, lightweight materials, these pipes and fittings ensure long-term durability and resilience.

- Optimized Air Flow: The system is designed to minimize pressure drop, ensuring consistent and efficient air flow throughout.

- Scalable Design: Modular and flexible, it can be easily expanded or modified to meet changing demands or configurations.

- Safety and Reliability: Leak-proof connections guarantee a safe working environment, reducing the risk of downtime due to maintenance.

Applications

The John Guest Ring Main System is ideal for a range of industries, including:

- Manufacturing: Essential for factories and production lines where reliable compressed air supply is critical.

- Automotive: Used in car workshops and assembly lines for efficient tool operation and automation processes.

- Healthcare: Supports medical and dental facilities with dependable air supply for various equipment.

- Food and Beverage Processing: Provides clean, uncontaminated air essential for food-grade applications.

- Laboratories: Ensures precise and controlled air distribution for research and testing environments.

How To Connect & Dismount John Guest Compressed Air Fittings

Connecting Push-Fit Fittings

- Preparation: Begin by ensuring the pipe is cut square. The use of a John Guest pipe cutter is recommended for rigid nylon pipes, and an aluminium pipe cutter for aluminium pipes. After cutting, inspect the pipe end. Remove any burrs or sharp edges to prevent damage to the O-Ring, which is crucial for maintaining a leak-free system.

- Making the Connection: Push the pipe firmly into the fitting up to the pipe stop. It's important to ensure that the pipe is inserted straight and not at an angle.

- Securing the Connection: To verify the connection is secure, give the pipe a gentle pull. It should remain firmly in place if properly connected. Before commencing use, it's essential to test the system under normal operating conditions to check for leaks.

Demounting Push-Fit Fittings

- Safety Precaution: Before demounting, confirm that the system has been depressurized. This is a critical safety step to prevent injury or damage.

- Demounting the Fitting: Push the collet squarely towards the body of the fitting. With the collet held in place, gently pull the pipe out of the fitting. John Guest fittings are designed for reuse, so they can be re-installed as needed following the proper connection procedure.

Connecting and Demounting Screw Cap Fittings

- Connecting Screw Cap Fittings: Insert the pipe into the fitting, then secure it by turning the screw cap a quarter turn. This locks the collet and minimizes the pipe’s lateral and sideways movement, ensuring a stable and reliable installation.

- Demounting Screw Cap Fittings: To disconnect, loosen the screw cap with a quarter turn. While holding the collet towards the fitting, gently pull the pipe to release it.

As with push-fit fittings, screw cap fittings are also reusable, enabling them to be employed in various applications as needed.

By following these steps, you can ensure a successful installation or removal of John Guest push-fit and screw cap fittings, maintaining the integrity and performance of your pneumatic or plumbing system. Always adhere to John Guest’s guidelines for the best results and system longevity.

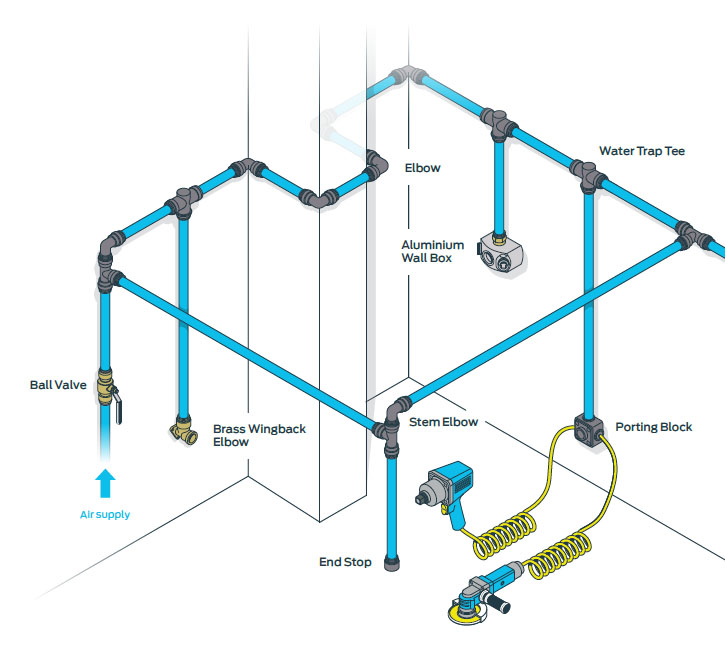

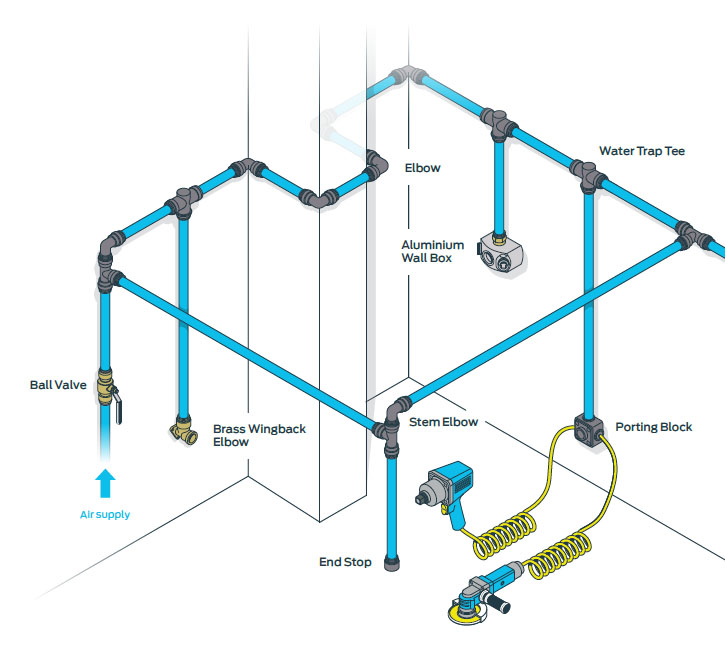

Example Installation

The John Guest Air & Pneumatics system provides swift and effortless assembly from the compressor straight to the air line, extending to the entire ring main and branching off to various points of use.

Downloads

If you require any further information, our excellent customer service team is here to help so please call us on 01794 835835.