Geberit Mapress: A Guide To Press Fit

Everything you'll ever need to know about Geberit Mapress

Published: 27th November 2024

In this guide, you'll learn everything you need to know about Geberit Mapress from the basics of what is press fit all the way through to installation.

We hope this guide can answer your questions but should you need further advice please get in contact with us.

Let's get started!

What is Geberit Mapress?

Geberit Mapress is a high-quality press-fit piping system designed to provide safe, reliable, and efficient solutions for transporting fluids and gases across various applications. It is widely used in residential, commercial, and industrial environments, offering a modern alternative to traditional connection methods like welding, threading, or soldering.

What are the key features of Geberit Mapress?

Material Versatility

Geberit Mapress offers system pipes and fittings in multiple materials to suit diverse requirements:

- Stainless Steel: High corrosion resistance, ideal for potable water, heating, and industrial applications.

- Copper: Known for its durability and reliability in high-pressure and high-temperature environments.

- Carbon Steel: An economical choice for closed circuits like heating systems, available with protective coatings for enhanced durability.

- CuNiFe (Copper-Nickel-Iron Alloy): Exceptional corrosion resistance, suitable for applications involving saltwater, such as shipbuilding.

Wide Range of Applications

The system is engineered for flexibility across various installations, including:

- Potable Water Supply: Ensures hygienic and safe drinking water delivery.

- Heating Systems: Efficiently handles high temperatures in residential and commercial heating.

- Cooling and Refrigeration: Suitable for chilled water and refrigeration pipelines.

- Gas Installations: Certified for natural gas and liquefied petroleum gas systems.

- Fire Protection: Applicable in sprinkler and other fire suppression systems.

- Industrial and Shipbuilding: Meets the rigorous demands of industrial processes and marine environments.

Reliable Press-Fit Technology

Geberit Mapress utilises advanced press-fit technology, offering:

- Leak Path Feature: Unpressed connections are designed to be visibly leaky during pressure tests, ensuring any unpressed fittings are easily identified and corrected.

- Defined Jaw Guide: Ensures precise positioning of pressing jaws, preventing misalignment and ensuring durable connections.

Comprehensive Range of Fittings and Seals

The system includes over 500 different fittings and various seal ring materials to accommodate specific media and temperature requirements, enhancing its adaptability.

Enhanced Safety and Efficiency

By eliminating the need for soldering or welding, Geberit Mapress reduces fire risks and accelerates installation times, contributing to overall project efficiency.

In summary, Geberit Mapress stands out for its material versatility, broad application range, reliable press-fit technology, extensive fittings and seals, and enhanced safety and efficiency, making it a dependable choice for modern piping installations.

Geberit Mapress Fittings vs. Traditional Fittings: What's the Difference?

When selecting fittings for piping systems, it’s important to consider how different connection methods impact installation efficiency, durability, safety, and suitability for various applications. Press fittings, such as Geberit Mapress, offer a modern, efficient alternative to traditional options like compression, threaded, and welded or soldered fittings. The table below highlights key differences between these fitting types, helping you determine the best choice for your specific needs.

| Feature | Mapress Press Fittings | Compression Fittings | Threaded Fittings | Welded/Soldered Fittings |

| Joining Method | Pressed with a tool around O-ring seal | Uses a nut and ferrule to compress seal | Screws into threads for connection | Heat is used to melt material for a bond |

| Speed of installation | Very fast | Moderate | Slow | Slow |

| Leak Protection | Integrated leak detection on testing | Relies on manual tightening | May loosen over time | Permanent when done correctly |

| Safety | No hot works, no fire risk | Safe | No fire risk | Requires flames or heat |

| Durability | Long-lasting, leak-proof if pressed correctly | May weaken with vibrations or movement | Durable but may loosen over time | Extremely durable |

| Tools Required | Pressing tool and jaws | Spanner or wrench | Pipe wrench | Soldering or welding equipment |

| Applications | Water, gas, heating, industrial uses | Low-pressure systems, DIY, plumbing | Industrial or heavy-duty applications | Plumbing, gas, and industrial pipelines |

What applications is Geberit Mapress suitable for?

Choosing the right material for a piping system is crucial to ensuring performance, durability, and compliance with application-specific requirements. Different materials offer unique properties that make them suitable for various uses, from potable water and gas distribution to industrial, marine, and fire protection systems. The overview below outlines the key applications for each material, helping you select the most appropriate option for your project.

Potable Water Systems

- Stainless Steel: Offers high corrosion resistance, ensuring hygiene and durability in drinking water systems.

- Copper: Commonly used due to its pressure resistance and suitability for potable water.

Heating Systems

- Carbon Steel: Economical option for closed heating circuits where external corrosion is not a concern.

- Stainless Steel: Used where higher resistance to corrosion is required.

Gas Applications

- Stainless Steel: Used for transporting natural gas, liquefied petroleum gas (LPG), and biogas, especially in industrial and commercial settings where high corrosion resistance is required.

- Copper: Suitable for gas supply in domestic and commercial installations.

Fire Protection Systems

- Carbon Steel: Ideal for wet fire suppression systems.

- Stainless Steel: Preferred for sprinkler systems requiring high corrosion resistance.

Industrial and Technical Applications

- Stainless Steel: Excellent for transporting aggressive media like chemicals, technical fluids, and high-purity liquids.

Marine Applications

- Stainless Steel: Used for high-resistance applications like seawater cooling systems.

- CuNiFe: Excellent corrosion resistance in saltwater, commonly used in shipbuilding, offshore platforms, and other marine applications.

Cooling and Refrigeration Systems

- Stainless Steel: Suitable for both chilled water and refrigeration systems, especially in industries where hygiene is critical.

- Carbon Steel: Economical option for non-corrosive environments.

Which Geberit Mapress seal ring is right for your application?

Geberit Mapress offers a variety of seal rings, each designed for specific applications to ensure reliability, safety, and performance across diverse systems. The choice of seal ring depends on the medium, temperature, and system requirements, with each type offering distinct characteristics such as chemical resistance, heat tolerance, or suitability for gas or water systems. The guide below outlines the uses and properties of each seal ring, helping you select the most appropriate option for your installation needs.

CIIR (Chlorobutyl Rubber) – Black Seal Ring

- Applications:

- Hot and cold potable water systems

- Heating water

- Cooling water (with or without antifreeze agents)

- Service water

- Compressed air (oil purity class 0–3)

- Inert gases

- Characteristics:

- High resistance to ageing and ozone

- Suitable for a wide range of water qualities

EPDM (Ethylene Propylene Diene Monomer) – Black Seal Ring

- Applications:

- Hot and cold potable water systems

- Heating water

- Cooling water without antifreeze agents

- Service water

- Compressed air (oil purity class 0–3)

- Inert gases

- Characteristics:

- Excellent resistance to heat, ozone, and ageing

- Not suitable for oil-based media

FKM (Fluoroelastomer) – Blue Seal Ring

- Applications:

- Solar thermal systems

- Mineral oils

- Fuels

- Compressed air (oil purity class 0–X)

- Characteristics:

- High chemical resistance

- Suitable for high-temperature applications

HNBR (Hydrogenated Nitrile Butadiene Rubber) – Yellow Seal Ring

- Applications:

- Natural gas

- Liquefied petroleum gas (LPG)

- Biogas

- Characteristics:

- High resistance to oils and gases

- Designed specifically for gas applications

FPM (Fluoroelastomer) – Red Seal Ring

- Applications:

- Fire extinguishing systems (wet/dry)

- Sprinkler systems

- Characteristics:

- Excellent heat resistance

- Suitable for systems requiring high-temperature endurance

FKM (Fluoroelastomer) – White Seal Ring

- Applications:

- Saturated steam systems

- Characteristics:

- High resistance to steam

- Suitable for cyclic operation

How do I install a Geberit Mapress piping system?

Below is a brief guide to the six stages of pressing a Geberit Mapress fitting. For full instructions, please consult the manufacturer's documentation.

- Cut the Pipe to Length

- Ensure the pipe is the correct length

- Deburr the inside and outside of the pipe

- Smooth the inside and outside edges to prevent damage to the seal ring

- Clean away debris from the pipe ends

- Mark the Insertion Depth

- Use an insertion depth marker for precise measurement

- Prepare the Fitting

- Remove the protection plug from the fitting

- Visually inspect the seal ring for any damage

- Insert the Pipe

- Push the pipe into the fitting until the insertion depth is met

- Press the Joint

- Use the appropriate pressing jaw or collar to align and press the connection

- Ensure alignment during the pressing process

- Final Check

- Remove the pressing indicator to complete the installation

Can Geberit Mapress be used for compressed air?

Yes, Geberit Mapress is highly versatile and suitable for use in compressed air systems across ISO 8573-1 oil purity classes (0–X). The system’s performance depends on the pipe material, diameter, and seal type used, as well as the operating conditions, including pressure and oil content.

Below is a detailed breakdown of the materials, seal options, and their suitability.

Geberit Mapress material compatibility for compressed air

Geberit Mapress offers materials tailored to a variety of compressed air applications, each with specific pressure and diameter limitations.

Mapress Stainless Steel

- Oil Purity Classes: Suitable for all classes (0–X), including oil-free systems.

- Maximum Operating Pressure by Diameter:

- 25 bar: 12–54mm.

- 16 bar: 76.1mm.

- 12 bar: 88.9mm–108mm.

- High resistance to corrosion, making it suitable for oil-free and humid environments.

- Compatible with all oil purity classes (0–X).

- Can handle high operating pressures of up to 25 bar for smaller diameters (d12–d54 mm).

- Long lifespan, making it ideal for medical, pharmaceutical, and food-grade applications.

- Higher initial cost compared to carbon steel.

- Heavier material, which may impact installation in large systems.

Mapress Carbon Steel

- Oil Purity Classes: Suitable for all classes (0–X).

- Maximum Operating Pressure by Diameter:

- 25 bar: 12mm–28mm.

- 16 bar: 35mm–54mm.

- 12 bar: 66.7mm–108mm.

- Cost-effective solution for general industrial use.

- Suitable for systems with moderate to high oil content (Classes 2–X).

- Can handle operating pressures of up to 25 bar for smaller diameters (12mm–28mm).

- Prone to corrosion in oil-free or humid environments without proper protective coatings or maintenance.

- Lower pressure limits for larger diameters (66.7mm–108mm: 12 bar).

- Not suitable for ultra-clean applications, such as medical or food-grade systems.

Mapress Copper

- Oil Purity Classes: Suitable for all classes (0–X), especially ultra-clean air applications.

- Maximum Operating Pressure by Diameter:

- 16 bar: 12mm–54mm.

- 10 bar: 66.7mm–88.9mm.

- 8 bar: 108mm.

- Naturally antimicrobial and highly resistant to internal corrosion.

- Ideal for ultra-clean compressed air applications, including laboratories and healthcare settings.

- Suitable for all oil purity classes (0–X).

- Lower maximum operating pressures compared to stainless and carbon steel:

- 16 bar for smaller diameters (12mm–54mm).

- 10 bar for 66.7mm–88.9mm and 8 bar for 108mm.

- Prone to theft due to the high value of copper as scrap material.

- Higher material costs and more delicate handling during installation.

Sealing Elements and Oil Purity Classes

Geberit Mapress provides two types of sealing elements, each suitable for specific oil purity classes:

- Oil Purity Classes: Suitable for Classes 0–3.

- Applications: Oil-free or low-oil compressed air systems.

- Advantages:

- Resistant to ageing and temperature variations.

- Ideal for oil-free or low-oil systems.

- Oil Purity Classes: Suitable for all Classes 0–X.

- Applications: Systems with moderate to high oil mist (Classes 4–X).

- Advantages:

- Exceptional resistance to oils and lubricants.

- Reliable under high temperatures and pressures.

Oil Purity Classes of Compressed Air (ISO 8573-1)

Compressed air is classified into purity classes based on oil content, ranging from Class 0 (ultra-clean) to Class X (heavily contaminated).

Purity Classes and Seal Recommendations:

| Purity Class | Oil Content (mg/m³) | Recommended Seal |

| Class 0 | No detectable oil | CIIR Black or FKM Blue |

| Class 1 | ≤ 0.01 | CIIR Black or FKM Blue |

| Class 2 | ≤ 0.1 | CIIR Black or FKM Blue |

| Class 3 | ≤ 1 | CIIR Black or FKM Blue |

| Class 4 | ≤ 5 | FKM Blue |

| Class 5 | ≤ 25 | FKM Blue |

| Class X | > 25 | FKM Blue |

Summary of Operating Pressures by Material

| Material | Diameter (mm) | Maximum Operating Pressure (bar) |

| Stainless Steel | 12 – 54 | 25 |

| 76.1 | 16 | |

| 88.9 – 108 | 12 | |

| Carbon Steel | 12 – 28 | 25 |

| 35 – 54 | 16 | |

| 66.7 – 108 | 12 | |

| Copper | 12 – 54 | 16 |

| 66.7 – 88.9 | 10 | |

| 108 | 8 |

Additional Considerations

Operating Pressure: Always verify the system’s operating pressure against the diameter-specific limits for the chosen material.

Corrosion Protection: Use stainless steel or copper for oil-free or humid environments to avoid rust issues with carbon steel.

Temperature Range: CIIR seals are suitable for moderate temperatures. FKM seals are ideal for higher temperatures and oil-lubricated systems.

System Maintenance: Regular maintenance is essential, particularly for oil-lubricated systems, to prevent excessive contamination.

Compliance: Ensure compliance with local standards and regulations, especially for high-purity air applications.

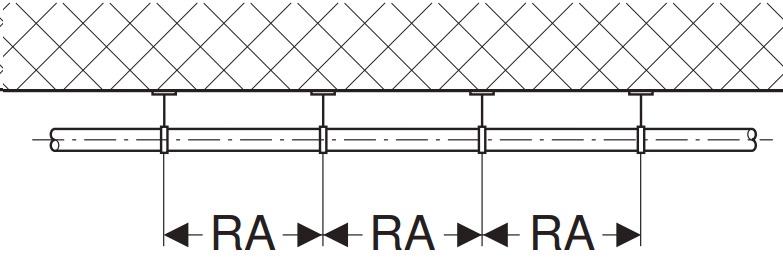

How often does mapress pipe need to be supported?

Maximum pipe bracket spacing and load per pipe bracket for Geberit Mapress Stainless Steel for drinking water installations

| d (mm) | RA (1) As reccomended by Geberit (M) | F (N) | RA According to EN 806-4 | F (N) |

| 12 | 1.5 | 5.3 | 1.0 | 3.5 |

| 15 | 1.5 | 7.3 | 1.0 | 4.8 |

| 18 | 1.5 | 9.4 | 1.2 | 7.5 |

| 22 | 2.5 | 23.2 | 1.8 | 16.7 |

| 28 | 2.5 | 33.0 | 1.8 | 23.8 |

| 35 | 3.5 | 72.2 | 2.4 | 49.5 |

| 42 | 3.5 | 95.1 | 2.4 | 56.2 |

| 54 | 3.5 | 140.6 | 2.7 | 108.4 |

| 76.1 | 5.0 | 389.8 | 3.0 | 233.9 |

| 88.9 | 5.0 | 500.8 | 3.0 | 300.5 |

| 108 | 5.0 | 690.4 | 3.0 | 414.3 |

RA: Pipe bracket spacing

F: Load per pipe bracket, pipe filled with water at 10 °C

(1): Different pipe bracket spacing applies for sprinkler, extinguishing and gas installations.

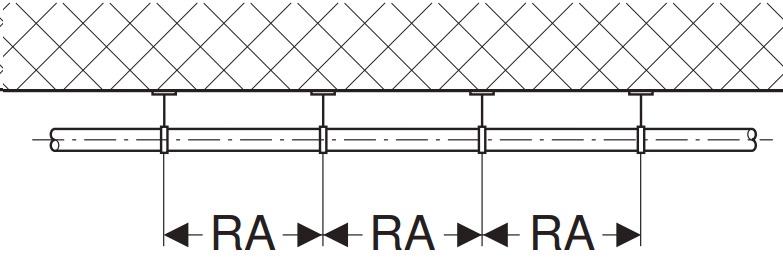

Maximum pipe bracket spacing RA and load per pipe bracket, sprinkler and extinguishing water systems

| d (mm) | RA (M) According to VdS CEA 4001 :2021-01 (1) | F (N) (2) |

| 22 | 2.0 | 18.6 |

| 28 | 2.0 | 26.4 |

| 35 | 2.0 | 41.3 |

| 42 | 2.0 | 54.4 |

| 54 | 2.0 | 80.3 |

| 76.1 | 2.0 | 156.0 |

| 88.9 | 2.0 | 200.4 |

| 108 | 2.0 | 276.2 |

F: Load per pipe bracket

(1): and Geberit recommendation

(2): Pipe, filled with water, 10 °C

What is the Geberit Industrial Application Tool?

The Geberit Industrial Application Tool is a digital solution designed to assist professionals in selecting suitable Geberit piping systems for various industrial applications. The tool evaluates the compatibility of piping systems, such as Mapress and FlowFit, based on specific media, operating conditions, and project requirements. Here is a detailed overview of its functionality and benefits:

What the Tool Does

- Media Compatibility Assessment: The tool determines the suitability of Geberit piping systems for transporting diverse substances, including: Industrial gases, compressed air, treated water, oils & cooling lubricants.

- Operating Conditions Evaluation: It analyses key factors such as: Temperature ranges, Operating pressures & Chemical resistance requirements.

- Customised Recommendations: Based on user inputs, the tool provides tailored suggestions for the most appropriate piping systems.

Key Benefits

- Efficiency: Saves time in project planning by streamlining the process of system selection.

- Reliability: Offers precise recommendations aligned with Geberit’s extensive testing and validation processes.

- User-Friendly Design: Simplifies navigation and interpretation, making it accessible to professionals with varying levels of expertise.

- Wide Applicability: Suitable for a range of industrial and engineering fields, including chemical processing, shipbuilding, and manufacturing.

By leveraging the Geberit Industrial Application Tool, professionals can confidently select the most appropriate piping solutions, minimising risk and ensuring long-term system reliability in complex industrial environments.

The Geberit Industrial Application Tool can be found here.