Fernco Puddle Flange

What is a Puddle Flange Used For?

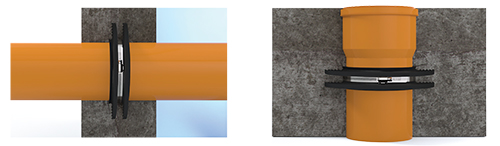

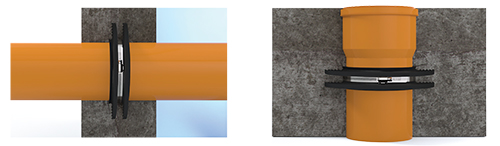

The Fernco (previously known as Flexseal) Puddle Flanges provide a watertight and pressure-tight seal for pipes passing through concrete walls, slabs, and other structures. Designed to prevent water ingress and the movement of radon gases along the exterior of cast-in pipe systems, they are essential for ensuring structural integrity in construction projects. The unique design of these flanges ensures a secure bond between the pipe and surrounding concrete, creating a long-lasting barrier against water, gases, and hydrocarbons.

As concrete cures, it naturally shrinks, creating potential ingress paths around embedded pipes. Fernco Puddle Flanges counteract this issue by compressing during the casting process and then expanding as the concrete sets, effectively blocking these pathways. This ensures a secure and permanent seal against external elements, making them a crucial component in waterproofing and gas protection applications.

Suitable for all standard pipe materials, including steel, plastic, stoneware, concrete, cast iron, and HDPE, these flanges are available in a wide range of sizes, including custom specifications to meet project requirements. They are commonly used in concrete walls, tanks, manhole chambers, shafts, foundation plates, and basements.

Key Features

- Watertight Seal: Provides a pressure-tight seal against water and gases, including radon, ensuring the safety and integrity of buildings.

- Versatile Application: Suitable for a wide range of pipe materials and sizes, from steel to HDPE.

- Easy Installation: Quick and simple to fit, offering a practical solution that does not require adhesives, sealants, or concrete.

- High Pressure Resistance: Confirmed to be pressure-tight to 8 bar through independent testing.

- Chemical Resistance: Made from high-quality EPDM, resistant to a variety of chemicals.

Specifications

- Size Range: Available from 15mm upwards.

- Material: High-quality EPDM rubber (EN 681) with stainless steel 304 clamp bands

- Pressure Rating: Moulded Puddle Flanges are watertight to 10bar

- Temperature Range: Suitable for -50°C to 80°C constant, and up to 100°C intermittently.

- Tightening Torque: 6Nm / 13Nm (as indicated on the product label).

- Compliance: Manufactured under ISO 9001:2015 quality standards

How and Where to Install a Puddle Flange

Installing the Fernco Puddle Flange involves:

- Pipe Preparation: Ensure the pipe where the flange will be fitted is clean. The flange's inside diameter may be smaller than the pipe's outside diameter and may require stretching over the pipe. Use pipe lubricant if necessary.

- Positioning the Flange: The fitted Puddle Flange should have an outside diameter 100/110mm larger than the pipe. Slide the flange onto the pipe, ensuring it's correctly positioned.

- Pouring Concrete: During the concrete pouring process, the rubber body of the Puddle Flange is compressed. Ensure a concrete cover of 50mm around the flange and use waterproof concrete for optimal results.

- Maintaining Seal: As the concrete cures and shrinks, the rubber will relax to maintain a watertight seal. Ensure the pipe is fully supported to withstand the concrete pouring process.

Downloads