Login / Register

John Guest Equal Tee

Useful Information

What is an Equal Tee used for?

The John Guest Equal Tee is an indispensable fitting designed to connect three pipes of equal size. This tee is crucial in air and pneumatic systems for branching or splitting the flow path, providing a symmetrical and efficient layout.

Key Features

- Robust Material: Crafted from strong acetal copolymer with a nitrile O-Ring, ensuring lasting durability and reliability.

- Simple Installation: Features an instant push-fit connection, facilitating easy and tool-free installation.

- Secure Locking Mechanism: Employs a unique collet locking design for a stable and leak-free connection.

- Fully Demountable: Allows for hassle-free maintenance and easy system alterations.

- High-Pressure Tolerance: Suitable for systems operating up to 10 bar, accommodating a diverse range of uses.

- Versatile Applications: Ideal for air, inert gases, vacuum applications, and suitable for potable liquids.

- Compatibility: Works seamlessly with nylon, powder-coated aluminium, LLDPE tubing, copper, PEXa, and other soft metal pipes.

Specifications

- Product Codes: PM0212E, PM0215E, PM0218E, PM0222E, PM0228E

- Available Sizes: 12mm, 15mm, 18mm, 22mm, 28mm

- Material: Acetal Copolymer with Nitrile O-Ring.

- Pressure Rating: Designed to handle air and pneumatics piping systems up to 10 bar.

- Temperature Range: Suitable for temperatures from -20°C to +70°C, ideal for various environmental conditions.

- Applications: Optimal for air, inert gases, vacuum applications, and potable liquids.

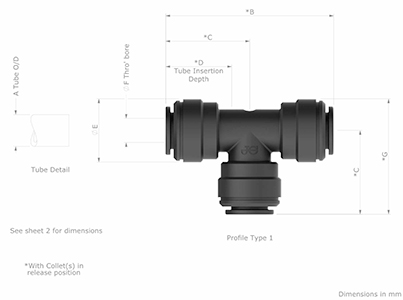

Technical Drawing

| SKU | John Guest Code | A (mm) | B (mm) | C (mm) | D (mm) | E (mm) | F (mm) | G (mm) |

| 382518 | PM0212E | 12 +0.05/-0.10 | 65 | 32.5 | 25.9 | 23 | 8.6 | 44 |

| 382519 | PM0215E | 15 +0.05/-0.10 | 74.6 | 37.3 | 28.3 | 27 | 12 | 50.8 |

| 382520 | PM0218E | 18 +0.05/-0.10 | 88.3 | 44.2 | 31 | 31.1 | 16 | 59.7 |

| 382521 | PM0222E | 22 +0.05/-0.10 | 97.7 | 48.9 | 34.3 | 35.5 | 19.2 | 66.6 |

| 382522 | PM0228E | 28 +0.05/-0.10 |

How to Install a John Guest Equal Tee

Simplified Installation Process:

- Preparation: Ensure the tubing or pipe is cut squarely and is free of damage or imperfections.

- Insertion: Insert the tubing into the tee until it reaches the tube stop, securing it with the collet locking system.

- Connection Confirmation: Gently tug on the tubes to confirm a secure and airtight connection.

- Disconnection: For removal, push the collet squarely against the fitting and pull the tube out.

- Adaptability: Perfect for various environments, including air and pneumatics systems, vacuum lines, and systems with potable liquids.

Advantages of the Installation Process:

- No Tools Required: The push-fit technology eliminates the need for tools, making installation quick and hassle-free.

- Time-Efficient: The installation process is significantly faster compared to traditional methods, enhancing productivity.

- Safety: The installation process requires no hot works, reducing risk and ensuring a safer working environment.