Login / Register

- Home

- Actuated Valves

- Electric Actuated Valves

Electric Actuated Valves

Electric actuated valves are essential components in various industrial processes, providing precise control and automation for fluid handling systems. At Pipestock, we offer a wide range of electric actuated valves, including butterfly valves, ball valves, T-port, and L-port configurations. These valves are ideal for applications requiring reliable and efficient flow control.

What is an Electric Actuator?

An electric actuator is a device that converts electrical energy into mechanical motion to control the position of a valve. It is an essential component in automated systems where precise control of fluid flow is required. Electric actuators are widely used in various industries due to their ability to provide accurate, reliable, and efficient operation.

Components of an Electric Actuator

- Electric Motor: The core component that generates rotational motion. The motor can be either AC or DC, with brushless motors being preferred for their efficiency and low maintenance requirements.

- Gearbox: A set of gears that reduces the motor speed while increasing torque, enabling the actuator to operate the valve even under high-pressure conditions.

- Drive Mechanism: Converts the rotational motion from the motor and gearbox into linear or rotary motion, which moves the valve stem or disc.

- Control Unit: Integrates with the actuator to provide precise control signals. Advanced actuators include microprocessors for better control and diagnostics.

Working Principle of an Electric Actuator

Electric actuators operate by receiving an electrical signal from a control system. This signal activates the electric motor, which generates rotational motion. The gearbox reduces the speed and increases the torque of this motion, which is then transferred to the drive mechanism. Depending on the valve type, the drive mechanism converts this motion to either rotate or push/pull the valve stem, thus opening or closing the valve.

For example, in a butterfly valve, the actuator rotates the valve disc to control fluid flow. In a ball valve, the actuator rotates the ball with a hole through its center, allowing or blocking fluid passage.

Types of Electric Actuators

- Quarter-Turn Actuators: Used for valves that require a 90-degree turn to open or close, such as ball and butterfly valves.

- Multi-Turn Actuators: Used for valves requiring multiple rotations for operation, like gate and globe valves.

- Linear Actuators: Convert rotational motion into linear motion to operate valves that need a straight-line movement.

What are the Advantages of an Electric Actuator Over Pneumatic?

- Precision: Electric actuators offer higher precision and control over valve position compared to pneumatic actuators. This is crucial for applications requiring accurate flow control.

- Energy Efficiency: Electric actuators are generally more energy-efficient, as they convert electrical energy directly into mechanical motion without the need for an intermediate medium like compressed air.

- Integration: They can be easily integrated with digital control systems, allowing for advanced monitoring and automation capabilities.

- Noise and Maintenance: Electric actuators are quieter and require less maintenance compared to pneumatic actuators, which involve more moving parts and potential for air leaks.

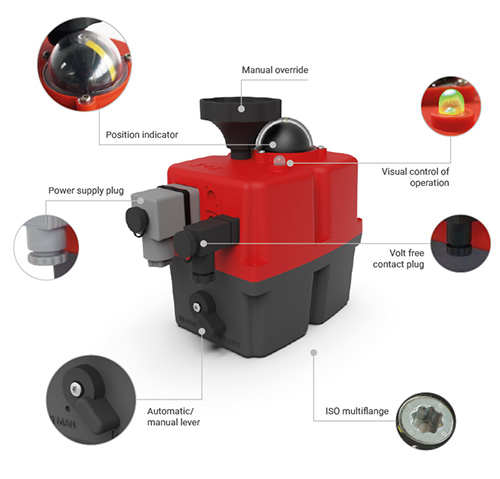

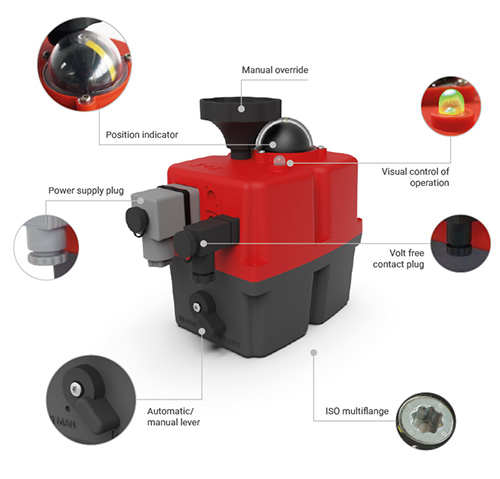

Key Features of an Electric Actuator

The J4C series electric actuator is designed to automate primarily 1/4 turn (90º) valves, such as butterfly and ball valves, made from plastic or metal. Key features include:

- Multi-Voltage: The system controls and transforms input current to 24 VDC, ensuring compatibility with various power sources.

- Brushless Motor: Brushless motors offer higher efficiency, reduced maintenance, and longer operational life compared to traditional brushed motors.

- Visual Operation Control (VCO): An external LED provides constant visual feedback on the actuator's operational status.

- Electronic Torque Limiter (ETS): Prevents damage by stopping the actuator when excessive torque is detected.

- Declutchable Manual Emergency Control (M.O.): Allows manual operation of the valve in case of electrical system failure.

- Auxiliary Micro Switches (VFC): Equipped with microswitches for transmitting open or closed position signals.

- Temperature Control (ATC): Maintains internal temperature to prevent damage from condensation.

What Industries Use Electric Actuated Valves?

Electric actuated valves are used across various industries due to their precision, reliability, and ease of integration. Key industries include:

- Water Treatment: For controlling the flow and treatment of water in municipal and industrial systems.

- Chemical Processing: Ensuring precise control of aggressive chemicals in manufacturing processes.

- HVAC Systems: Regulating heating, ventilation, and air conditioning systems for optimal performance.

- Oil and Gas: Managing the flow of hydrocarbons in extraction and processing facilities.

- Food and Beverage: Maintaining sanitary conditions and precise control in food production lines.

If you require any further information, our excellent customer service team is here to help so please call us on 01794 835835.